Notice - This website has asked me to notify you that it uses

cookies to store information on your computer, the cookie function is

out of my control as the site is hosted by Blogger (which has Google connections). Most cookies are used

to make a website work and others are used to help improve it by

providing some usage details (e.g. time spent on page, approximate

geographical location etc). I am not an expert on cookies and suggest

that you satisfy yourself that you understand cookies adequately and how

to manage them. If you want to limit the use of cookies you can adjust

your cookie preferences and also delete cookies, some browsers

also allow you to enable secret browsing. I hope this helps you to make

a conscious decision about cookie management.

Today was spent building the kit, pictures taken at various points below:

Four stepper motors, one has longer wires for filament feed

First fix stepper motors to bottom brackets

Two per motor

Then fit arms - good idea to invest in ball ended Allen keys for assembling many parts

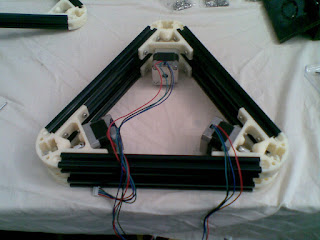

Assemble top parts into a triangle

Assemble bottom parts into a triangle (slide together at same time)

Fit belt pulleys

Fit hot end contact switch

Fit arms

Assemble roller sets

Fit limit switches to uprights

Fit rollers to arms

Assemble all the bits into a frame with rollers connected to arms

Assemble hot end into carrier

Fit and trim drive belts

Filament feed motor mounting position

Main board and display mounted and connected up

Power and USB connections

Glass bed (covered in what looks like masking tape) held in place with six screws and deeper nuts

Thoughts - generally quite fiddly to build and instructions sometimes lacked detail.

Some screws are only threaded into plastic which could become a weakness over time but they currently feel quite secure. One area of particular concern was the hot end hinge was not free floating against the micro switch, I spent a lot of time working the screws in and out to create a running clearance but with no slop. The adjustment of this seems quite vague too.

The nuts inside rails sometimes turn rather than grip, so they need to be held when tightening the screws, I wedged them with a small Allen key.

The main circuit board and display were easy to wire up and mount but there wasn't much wrap for double insulation, so I taped up the wires with black insulation tape. I decided to mount the filament feed motor on the side of the frame rather than the top as this seemed to give a smoother curve across the whole working range. This may change once tested and may depend on spool position.

Tomorrow the software.

No comments:

Post a Comment